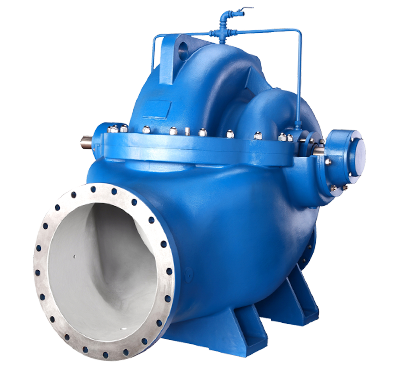

serie bleuQUANTUM | Q T |

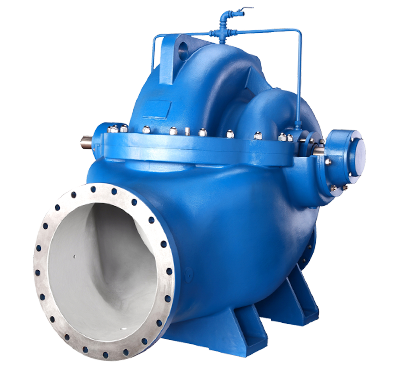

serie bleuQUANTUM | Q T |

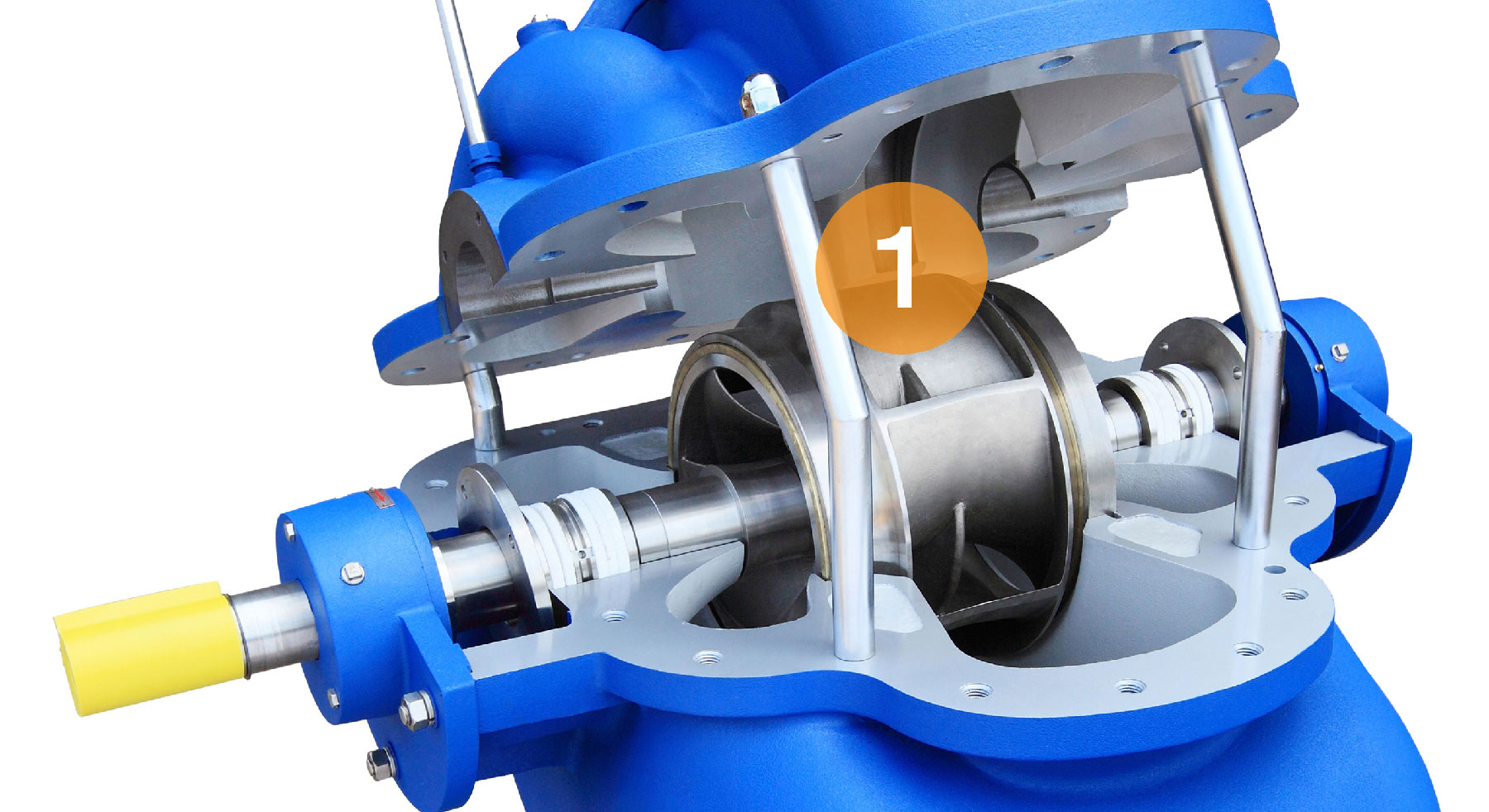

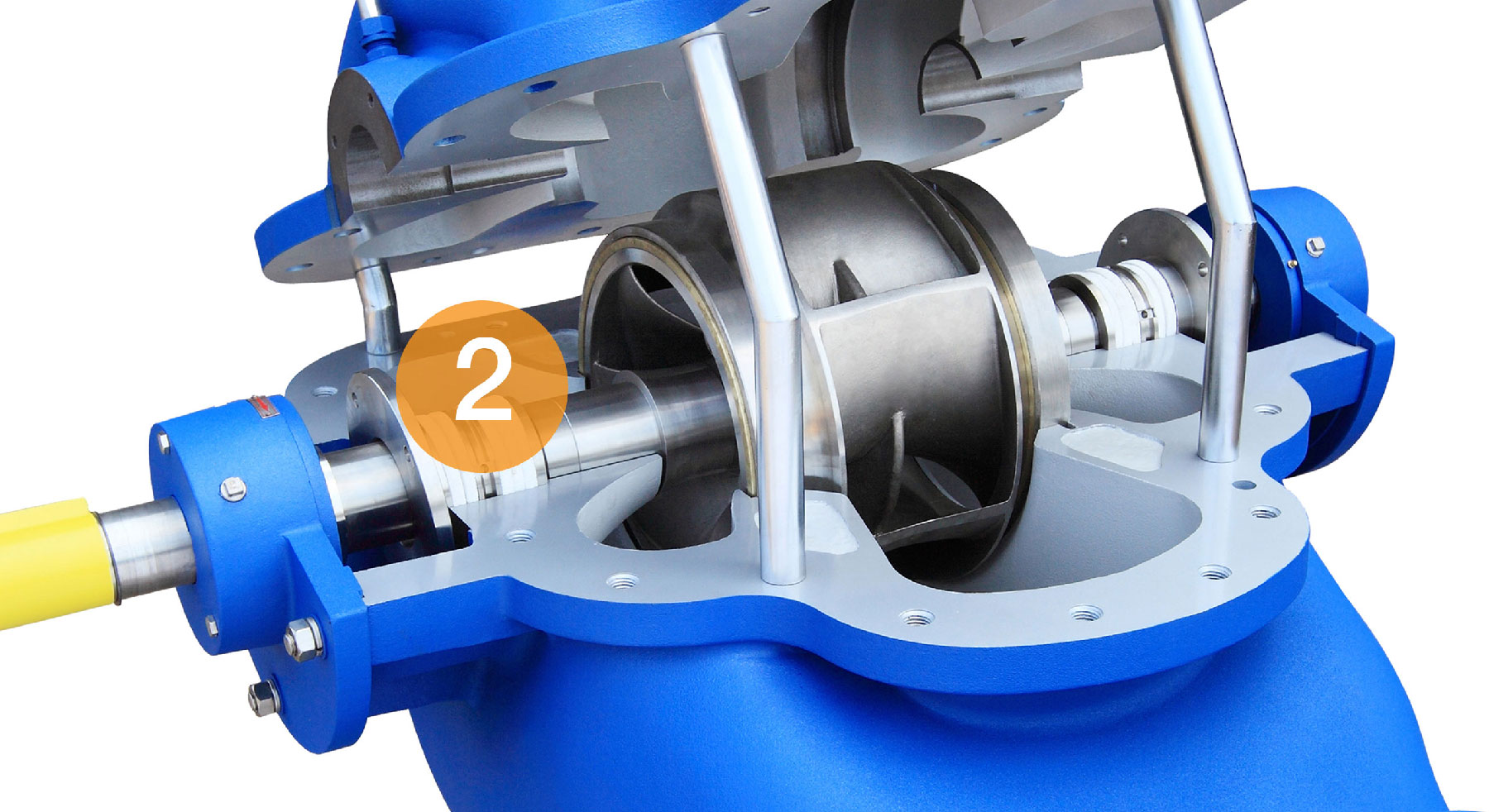

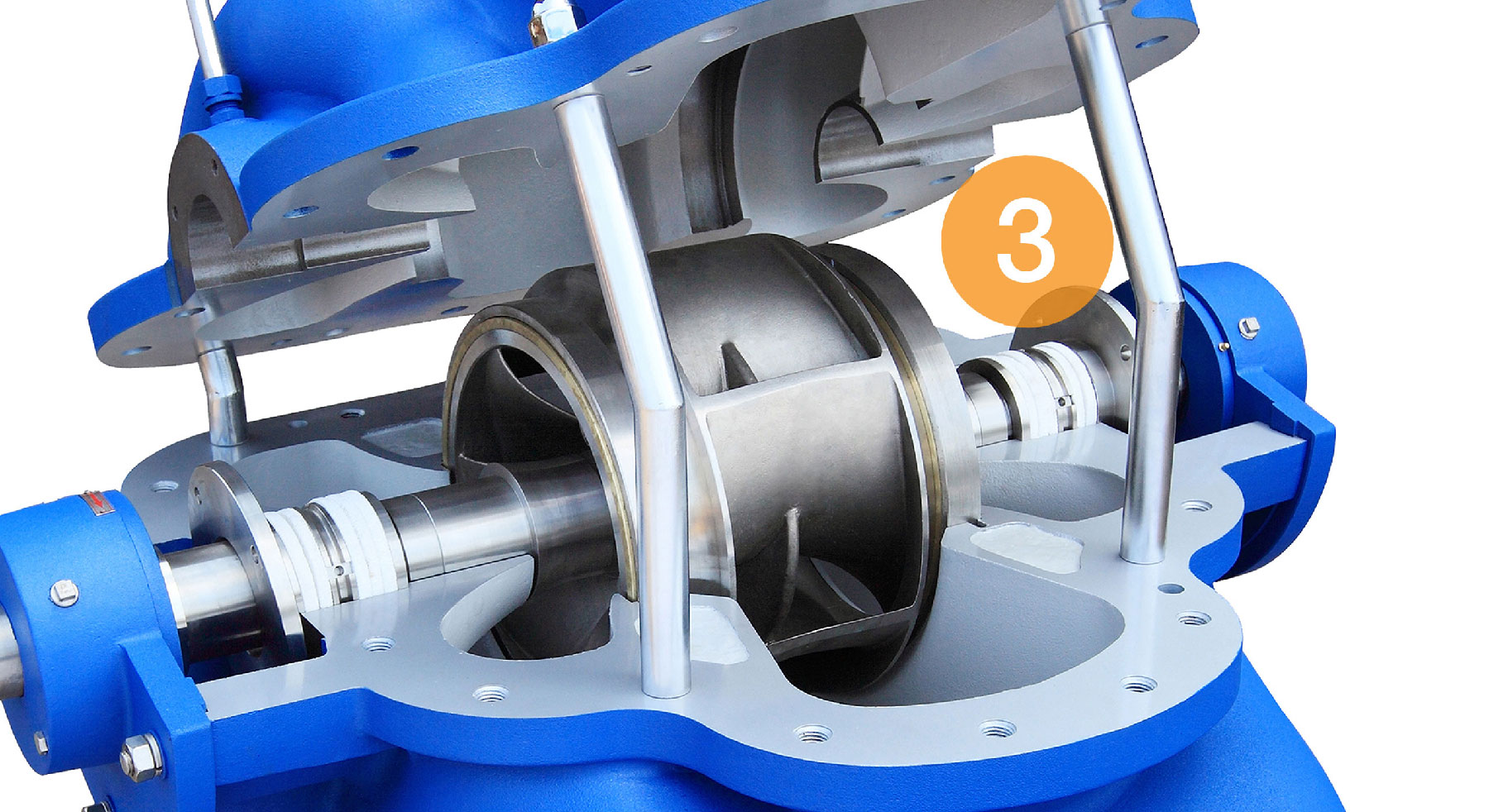

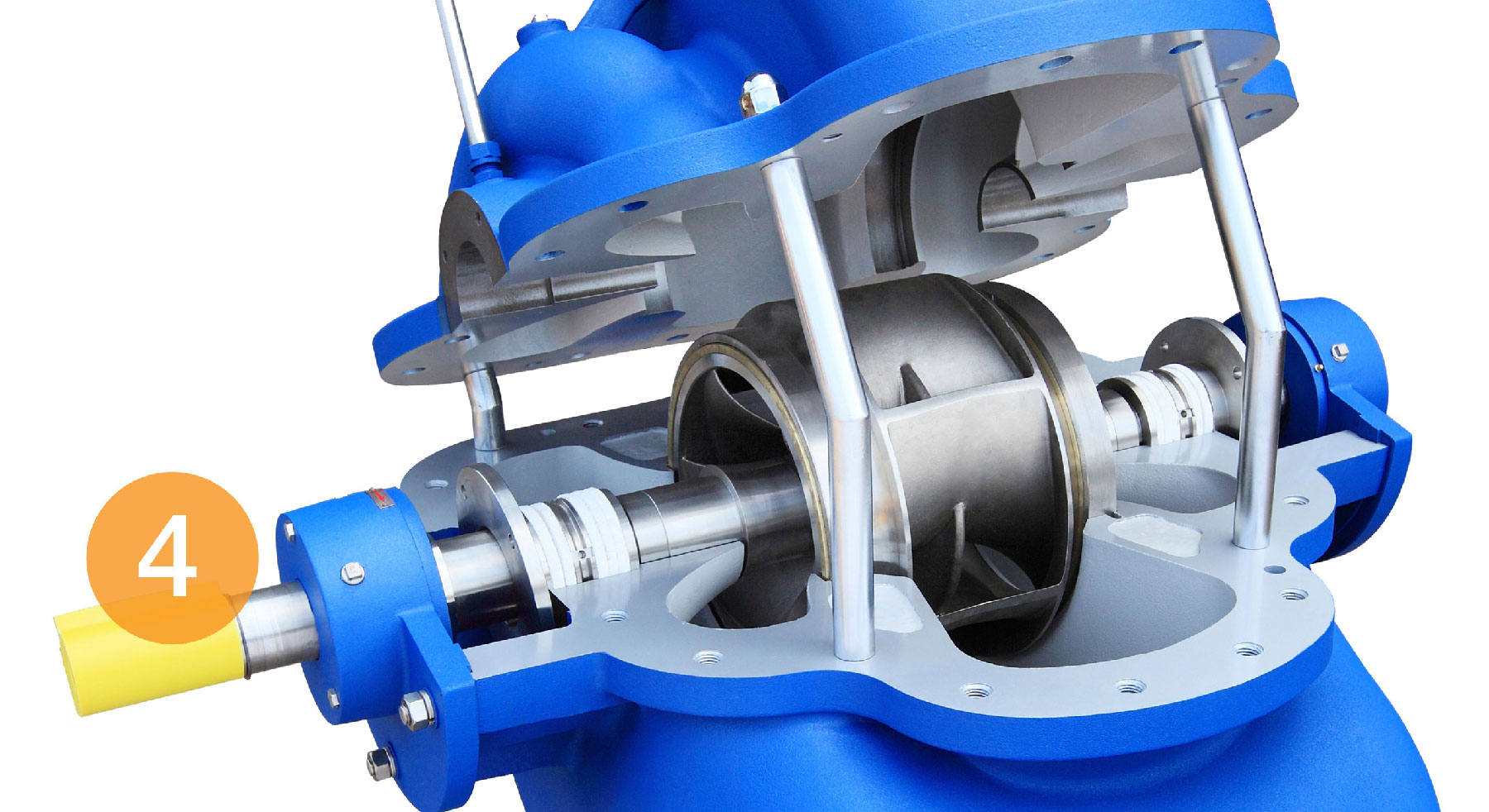

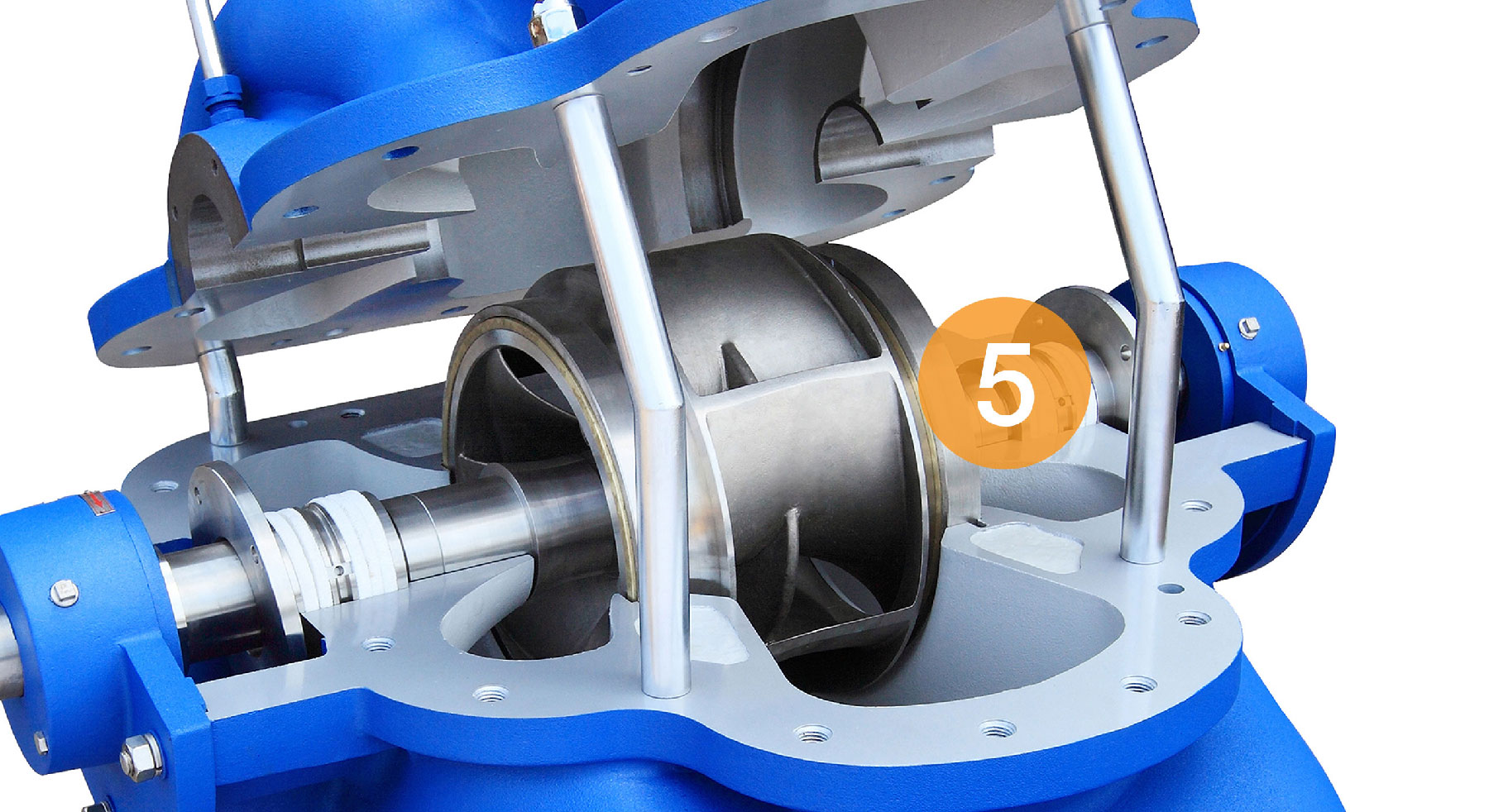

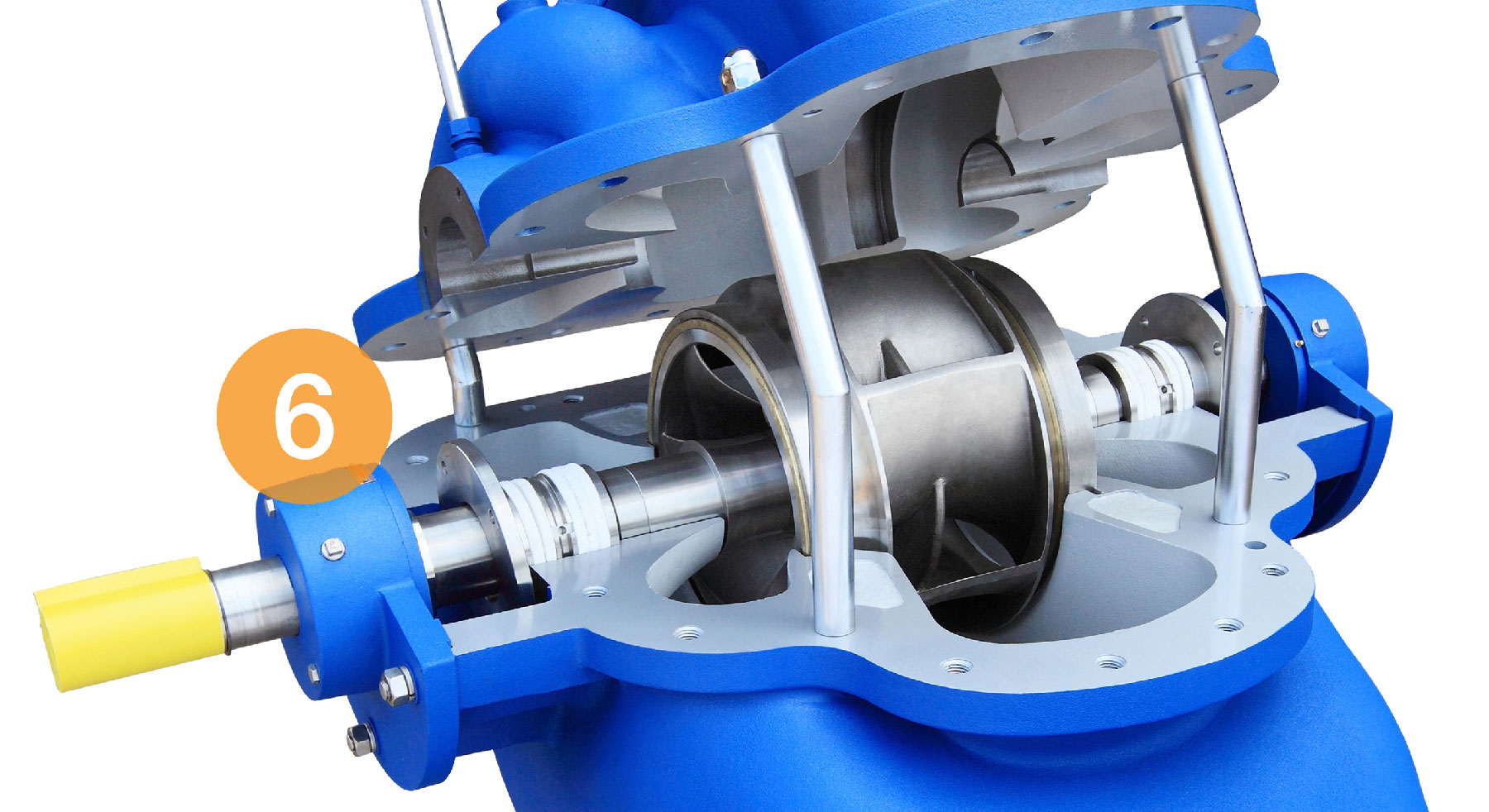

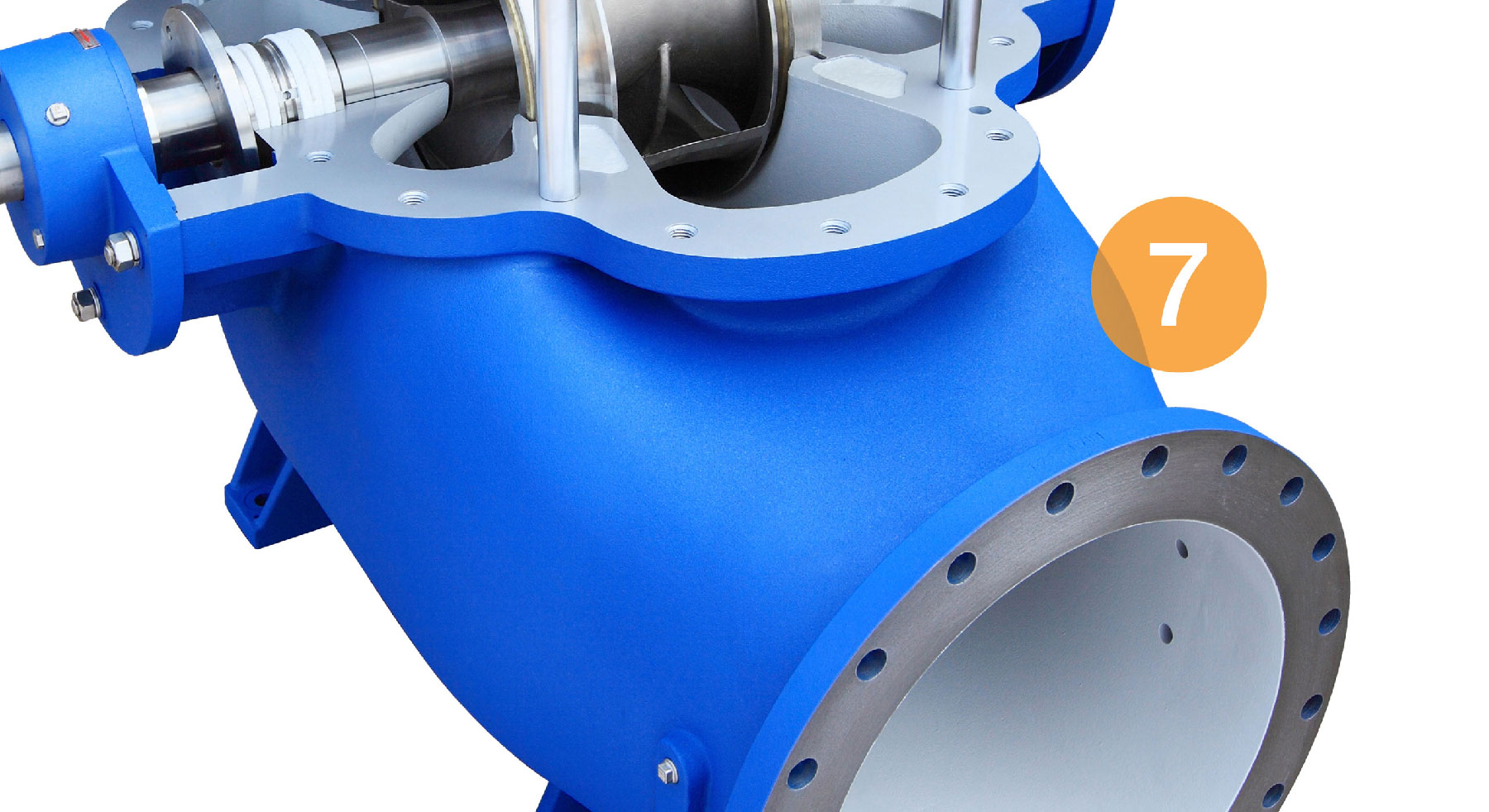

The Quantum series features a line of superior performance double suction horizontal split case centrifugal pumps, of robust design to meet today's demands in the industrial, municipal, agriculture and commercial applications. The range is designed with the tightest technical specification in mind, so as to achieve the highest level of efficiency and hyrdraulic performance for current and future process demands.

Incorporating advances in computer-aided technology, Quantum offers high efficiency performance, reliable & long life service resulting in energy-saving, less downtime & low maintenance cost.

applications.

Building services

General water transfer; chilled & condenser water circulation in air-conditioning systems and fire protection in office & apartment buildings, malls, hotels, hospitals, schools & institutions and airports.

District cooling

Heat exchanger, chilled & condenser water circulation.

Industrial

General water transfer, circulation & dewatering of water in sugar mills, steel mills, paper & pulp manufacture, desalination, chemical & petrolchemical plants, fertiliser plants, mines, power generation plant and in other industrial processes.

Utilities

Water intake and municipal waterworks, handling raw, clear, polluted and waste water. Flood control and other auxiliary services.

operating limits.

Liquid handled

Clear water

Working pressure

Working pressure range up to 150 bar, depending on pump models, material of construction and temperature of fluid handled.

Discharge pressure

Maximum pressure head up to 28 bar or 280 metres.

Operating temperature

Pumped medium up to 200 oC.

Operating speed

Nominal operating speed from 1,500 rpm to 2,900 rpm at 50Hz.

Flange

DIN 2501; BS 4504; ISO 7025/2 or ANSI B16.1

Flowrate

Maximum flowrates up to 7,000 litres/sec or 25,000 m3/hr.