serie bleuISO-MAGNA | I S M |

serie bleuISO-MAGNA | I S M |

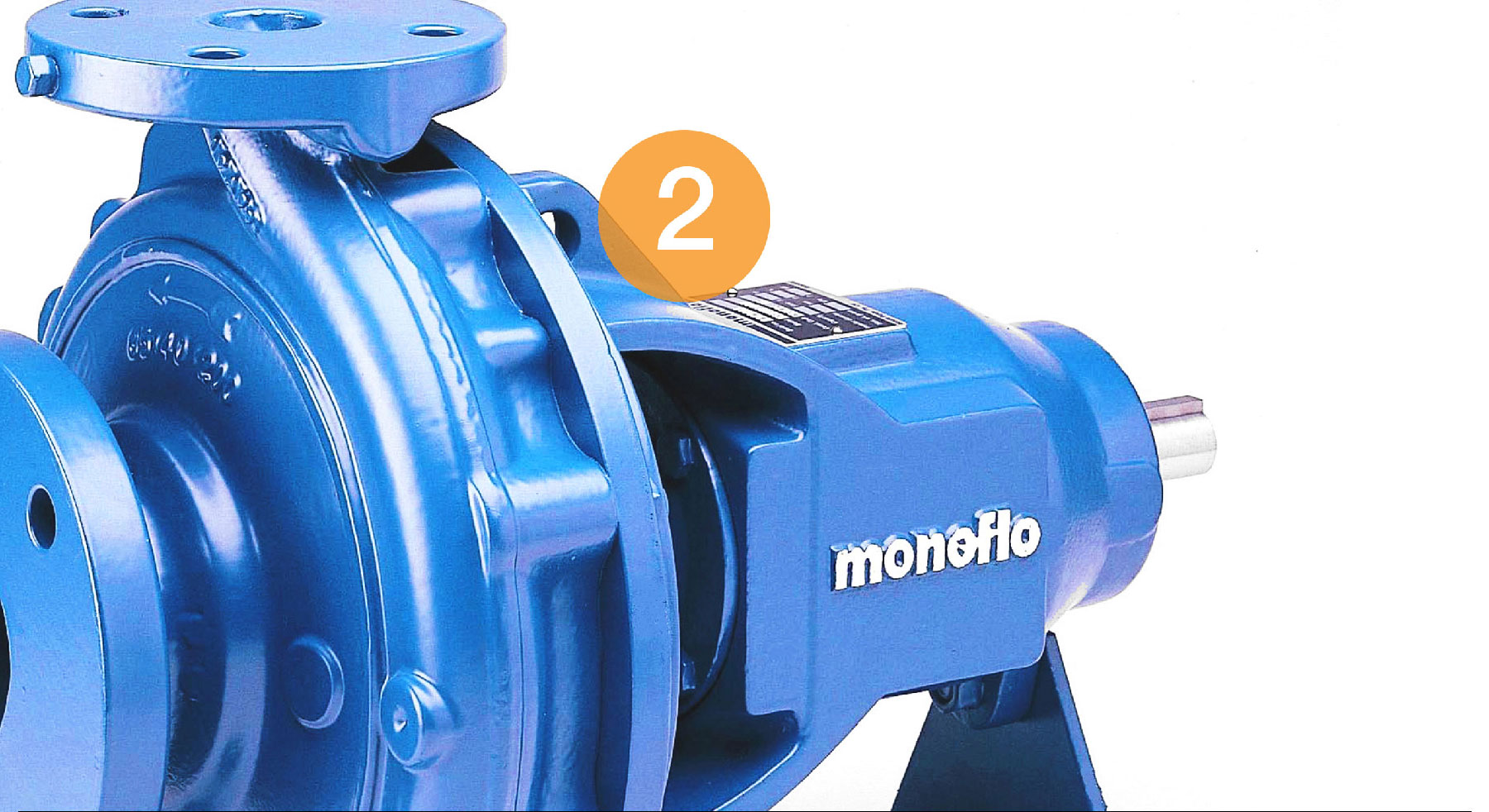

Conforming with ISO2858 Standard means dimensional interchangeability with other makes of pumps, manufactured to the same international standard, however because of design superiority Monoflo ISO-Magna exceed the performance standard.

Superior hydraulic design and manufacturing processes, make ISO-Magna a robust pump, ensuring extended life and performing at significantly higher efficiencies and greater performance at reduced running costs and minimum maintenance.

Depending on pumping requirements and specific applications, ISO-Magna can be engineered in various material executions, and seal types to meet application needs.

applications.

Building services

Water transfer & pressure systems; central air-conditioning systems; fire protection; swimming pools & water feature applications.

Industrial

Circulation for machine cooling, process water in paper& pulp, iron & steel mills and sugar industry; marine & shipbuilding; and other manufacturing processes.

MINING

Mine general water supply; mine dewatering; generation of power; mining process.

Agriculture

Irrigation; stock watering.

operating limits.

Liquid handled

Clean water or slightly-aggressive liquid compatible to pump material of construction.

Working pressure

Maximum working pressure up to 16 bar, (with exception of models at 10 bar). Pressure rating up to 24 bar available as option.

Flowrate

Maximum capacity up to 250 litres/sec or 900 m3/hr.

Discharge pressure

Maximum discharge pressure up to 16 bar or 160 metres.

Operating temperature

Temperature range of medium pumped, from - 15oC to 80oC. Higher temperature up to 105oC, with optional mechanical seals.

Operating speed

Maximum operating speed up to 2,900 r.p.m. at 50Hz and 3,600 r.p.m. at 60Hz.